Authentic innovations are created utopias that originate from technology but which only acquire value if man and his needs are at the centre, not technology for technology. 3D HOUSING 05 is an ambitious project in which beauty and speed are the classic qualities in a contemporary key

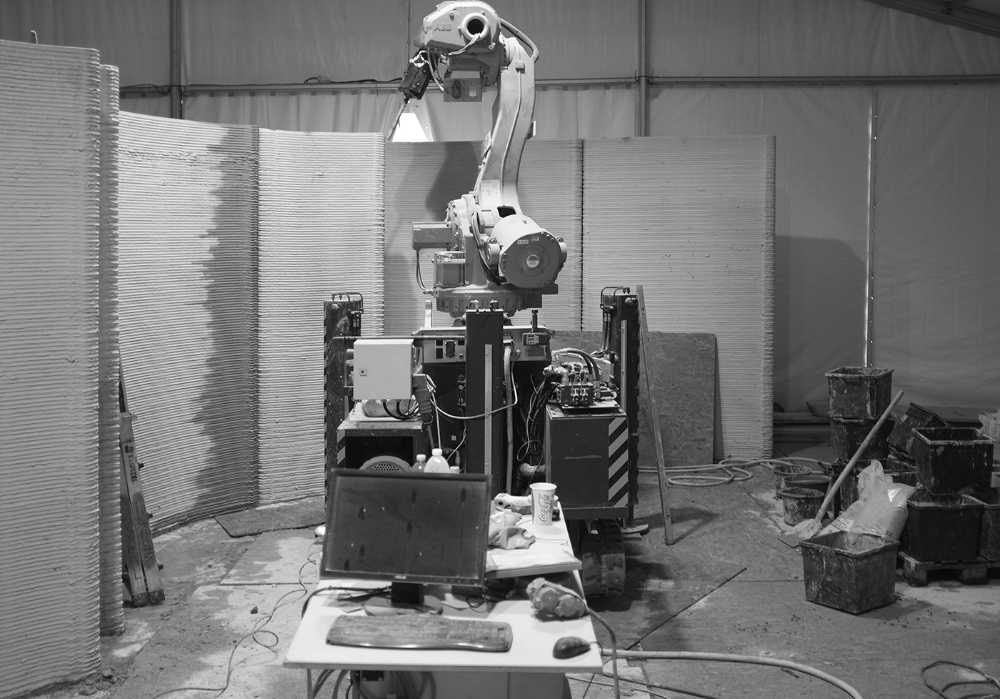

3D house printed on site. Sustainable and ecological made with technological cement

Massimiliano Locatelli, Locatelli Partners, presented 3D HOUSING 05, the first project in Europe of 3D home printed on site, which explores the infinite possibilities that 3D printers offer in the field of architecture and design

- #Europe

- #Italy

- #Furniture

- #New construction

- #Exhibition / Temporary Installation

- #Concrete

- #Interior

- #Architectures

- #Architecture

3D HOUSING 05 is a sustainable and ecological building made with technological cement. A new housing unit in every respect, which can be installed anywhere, in a short space of time, radically cutting costs but above all creating a new relationship between architect and the client. Freedom of form comes from the adaptability of the printer

Speed and versatility allow continuous evolution. The house can be demolished and rebuilt using its own debris, with zero impact. In a world where needs change quickly, the house loses its finished character to follow the personality and needs of those who live in it

3D HOUSING 05 is a first prototype of 100 sqm, made in a week in Milan in Beccaria Square. The shape of the housing unit, which is rounded and organic, fits naturally into the urban context. It consists of a living area, a kitchen, a sleeping area, a bathroom and a living roof, designed as a vegetable garden and a garden. The exteriors are made of cement, marked out by the casting of material: a texture that provides a natural foothold for creepers. The interiors, with portions of smoothed plaster walls, have an archetypal elegance underlined by attention to detail, brass frames and furnishings

Gallery

Photos: Luca Rotondo